|

|

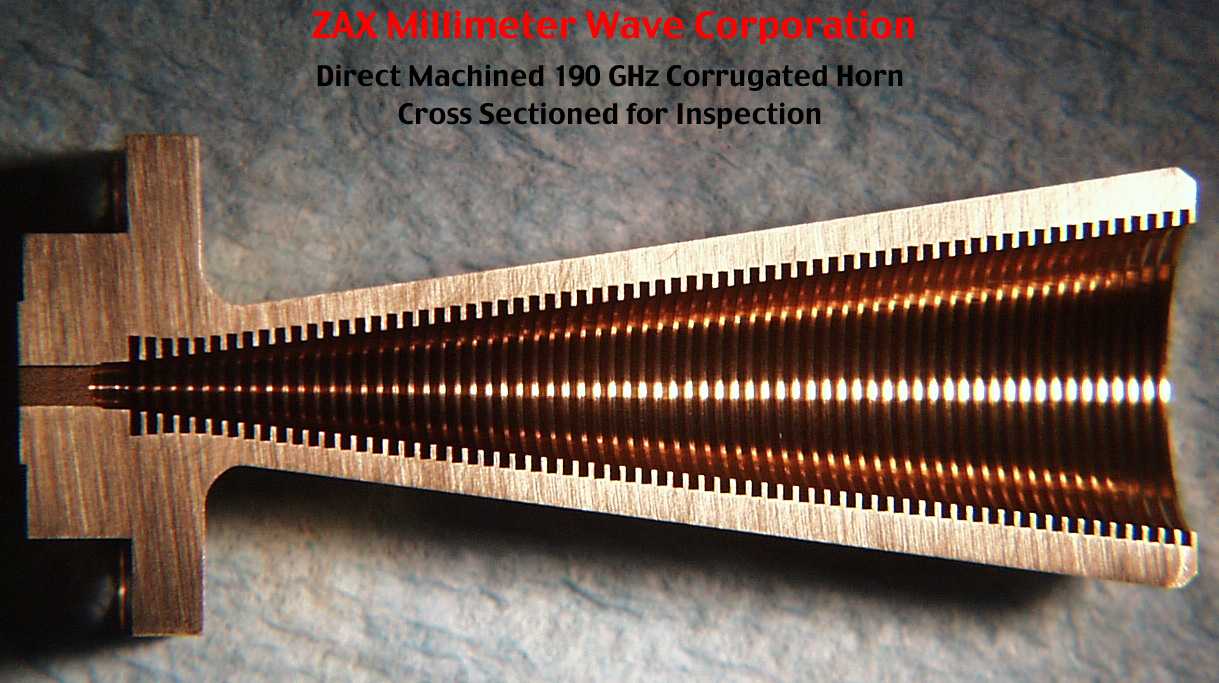

CUSTOM ANTENNA DESIGNS

ZAX will custom design various types of antennas for specific

applications. Corrugated conical horn antenna designs range from

low flare angle to large flare angle. Each design can be tailored

to applications including a stand alone horn, feedhorn-lens, horn-lens

and feedhorn-reflector combinations. The horns are designed for

a given operating bandwidth.

PERFORMANCE CONSIDERATIONS

Large flare angle (scalar) feedhorns can provide nearly constant

E and H pattern performance over an octave frequency bandwidth.

This design produces a large beamwidth and is normally used in

reflector-feedhorn or lens-feedhorn systems.

Low flare angle feedhorns are physically longer than scalar feedhorns,

yield narrow beamwidths and are typically utilized for narrow

bandwidth applications.

MECHANICAL AND COST CONSIDERATIONS

Fabrication processes are selected based upon electrical performance,

size, and cost requirements. Direct machining, or a three step

electroforming process can generally fulfill fabrication requirements.

DIRECT MACHINING - Large diameter, low frequency, large flare

angle, and short length corrugated feedhorns are normally candidates

for direct machining on a precision lathe. The throat of such

antennas is sufficiently large to provide clearance for cutting

tools. Direct machining is an economical single step fabrication

process.

ELECTROFORMING - The length of low flare angle feedhorns, the

diameter and depth of matching grooves near the intersection of

the circular waveguide and the corrugated conical flared sections

can restrict the tool clearance available for direct machining

operations. Such designs dictate a higher cost multiple step electroforming

process. Electroforming involves a three step process consisting

of: (1) Precision external machining of the internal geometry

of the circular waveguide and the conical corrugated grooved wall

envelope into the surface of an aluminum mandrel, (2) Electroforming

the final feedhorn configuration by electrochemically depositing

copper and nickel onto the mandrel surface until the desired feedhorn

wall thickness is achieved, (3) Removal of the mandrel by a chemical

etching process which selectively etches the mandrel material.